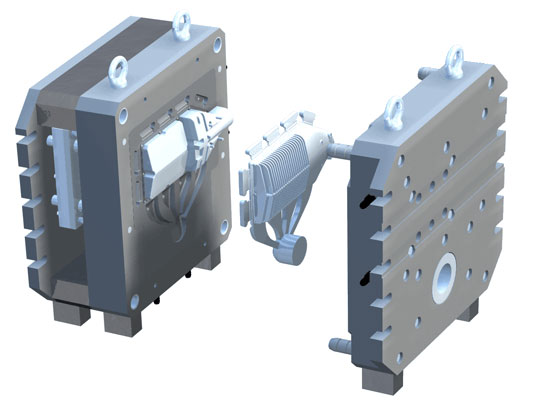

Molds

Engineering&Manufacturing Group (EMG) USA and Gesan Grup R.Moldova (Romania) manufacturer Injection Molds. It is a very important area of our business.

In the manufacture of molds carries a mandatory quality control in all stages of production. In the end build the new mold tests are conducted on the equipment of the customer.

The accuracy and quality of the working parts is provided by CNC milling machines, surface grinding, cylindrical grinding and jig boring machines, as well as Electrical Discharge Machining

INJECTION MOLDS

Rapid Prototype molds and low-volume molds produce real injection molded parts for functional testing. They can also serve as bridge tooling to fill the manufacturing gap for production tooling. The difference between rapid injection molding and a low-volume mold is in the details.

Production Molds are built to withstand higher volumes of molding cycles. They are made with P20 steel or NK80 stainless steel, and typically last over 100,000 cycles. Making design changes on production molds is possible with CAD file changes and reworking your mold accordingly.

Production starts with 30% down payment, with the rest paid only after you are satisfied with the testing sample.

We have 15 years experience in building customized molding tools for small businesses or large manufacturers. We strive to offer the best service with the best price. Price varies depending on the type of molding tools.

For an accurate quote, the specifications / info that we need are below:

- 1. Drawings in 3D files or flat

- 2. One PDF image of the drawing

- 3. Pictures on each 4 sides of the sample if you have one ( Not a must)

- 4. The material name that the mold will be used for

- 5. If you want us to handle the actual product manufacturing after tooling( We offer a special discount)

- 6. Numbers of the cavity

Export Molds

Family Injection Molds

Insert Molding